The Brayton Cycle, also known as the gas turbine cycle, is a thermodynamic cycle that describes the operation of gas turbines, a type of engine widely used in industrial, aeronautical, and power generation applications.

This cycle provides a detailed description of how thermal energy is converted to mechanical energy using a gas workflow.

Cycle processes

The Brayton cycle consists of four main thermodynamic processes:

- Isothermal compression.

- Constant pressure heating.

- Isothermal expansion.

- Constant pressure cooling.

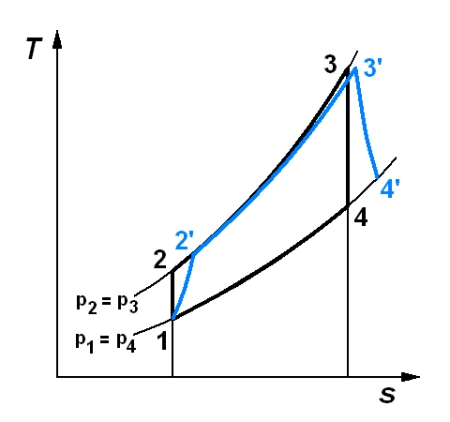

These processes are represented in a TS (temperature-entropy) and PV (pressure-volume) diagram, which allows the performance and characteristics of the cycle to be analyzed.

Isothermal compression

The cycle begins with isothermal compression, where ambient air is compressed adiabatically in a compressor, increasing its pressure and temperature.

This process is carried out so that the temperature of the gas remains constant, which requires the removal of the heat generated during compression.

Constant pressure heating

The compressed air is then directed into the combustion chamber, where fuel is injected and burned, generating a significant increase in the temperature and pressure of the gas at constant pressure.

Isothermal expansion

The next process is isothermal expansion, where hot gas expands through a turbine, converting some of the thermal energy into mechanical energy, which is used to drive the compressor and any load connected to the turbine shaft.

During this expansion, the temperature of the gas remains constant, and the work done by the turbine is calculated by the pressure-volume integral on the Pv diagram.

Constant pressure cooling

Finally, the cooled gas is routed through a heat exchanger or constant pressure chiller, where excess heat is removed before the cycle begins again. This process maintains the thermal efficiency of the cycle by preventing the exhaust gas from having too high a temperature.

Features of the Brayton cycle

An important feature of the Brayton cycle is its ability to operate in an open or closed system.

In an open system, the intake air is taken from the surroundings and discharged after passing through the turbine, while in a closed system, the air is continuously recirculated. This flexibility allows the cycle to be adapted to different applications and operating conditions.

Another important parameter is the maximum to minimum pressure ratio, which describes the pressure difference between the inlet and outlet of the turbine. A higher pressure ratio can increase turbine power output, but can also increase thermal and mechanical loads on system components.

Performance

The performance of the Brayton cycle can be evaluated by various parameters such as thermal efficiency, compression ratio, and maximum to minimum pressure ratio.

The thermal efficiency of the cycle is defined as the relationship between the net work done by the turbine and the heat supplied in the combustion chamber. Higher thermal efficiency indicates a more effective conversion of thermal energy into mechanical work.

The compression ratio, on the other hand, is the ratio between the maximum pressure and the minimum pressure in the cycle. A higher compression ratio usually leads to higher thermal efficiency as it increases the temperature difference between the turbine inlet and outlet. However, an excessive increase in compression ratio can increase compression losses and reduce cycle efficiency.

Application Examples

The Brayton cycle is used in a variety of both industrial and commercial applications due to its efficiency and versatility.

Some examples of these applications are:

- Gas turbines for electric power generation : Gas turbines operating on the Brayton cycle are widely used in power plants to generate electricity. These turbines can run on a wide range of fuels, including natural gas, oil and biogas. They are especially useful in combined cycle applications, where waste heat from the turbine is used to generate steam and power an additional steam turbine, thus increasing the overall efficiency of the plant.

- Aeronautical propulsion : These engines, also known as jet engines or turbofans, compress incoming air, heat it by burning fuel, and then expand it through a series of turbines to generate thrust. They are highly efficient in terms of thrust per unit of fuel consumption and are essential for modern aviation.

- Gas turbines for industrial applications : Gas turbines based on the Brayton cycle are used in a variety of industrial applications, such as gas compression, pump driving and power generation in remote installations or on offshore platforms. These turbines can run on a variety of fuels and can be tailored to meet a wide range of power and load requirements.

- Naval propulsion : Warships and merchant ships use gas turbines based on this thermodynamic cycle for propulsion. These engines offer high power relative to their weight and size, making them ideal for marine applications where space and weight are limited. Additionally, their ability to run on a variety of fuels makes them suitable for offshore operations.

- Space propulsion : The Brayton cycle is also used in propulsion systems for spacecraft. Closed-cycle rocket engines, which use a working fluid as a propellant and operate according to the principles of the Brayton cycle, are used for attitude control maneuvers and orbital changes in satellites and spacecraft.