In the study of physics and thermodynamics, a process is a change of state in a system where its thermodynamic properties, such as pressure, volume, and temperature, are altered through the transfer of energy in the form of heat or work. These processes are involved in the thermodynamic cycles of internal combustion (endothermic) engines, which are the engines commonly found in automobiles, motorcycles, and many other types of machinery.

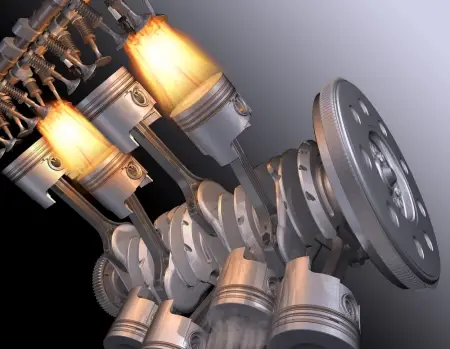

Endothermic engines convert the chemical energy of fuel (such as gasoline or diesel) into mechanical energy. This is achieved through thermodynamic cycles that occur within the engine cylinders. The main components of the engine include the piston, cylinder, intake valve, exhaust valve and crankshaft. The movement of the pistons inside the cylinders is what ultimately propels the vehicle.

The most important cycles in these engines are the Otto and Diesel cycles. In both cases, the thermodynamic processes that appear in their different stages are the following:

- Isobaric: Pressure remains constant while volume changes.

- Adiabatic: There is no heat exchange with the environment; pressure and temperature change due to compression or expansion of the gas.

- Isochoric (Isochoric): The volume remains constant as the pressure and temperature change.

Stages of the Otto cycle

One of the most common cycles that describes the operation of internal combustion engines is the Otto cycle. This cycle consists of four main stages: intake, compression, combustion (expansion) and exhaust.

1. Admission (isobaric process)

During the intake stroke, the intake valve opens and the piston moves down inside the cylinder. This allows the air and fuel mixture to enter the cylinder.

At this point, the process is isobaric, since the pressure inside the cylinder remains constant (equal to atmospheric pressure) while the volume increases. This increase in volume is due to the downward movement of the piston which creates more space inside the cylinder.

2. Compression (adiabatic process)

After the air-fuel mixture has entered the cylinder, the intake valve closes and the piston moves up, compressing the mixture.

This process increases the temperature and pressure of the mixture, but it is not an isobaric process, but rather an adiabatic one, because the pressure changes during compression.

3. Combustion and expansion (isochoric and then isobaric process)

The moment the piston reaches the top of the cylinder, the compressed mixture is ignited by a spark. The rapid combustion of the mixture produces a sudden increase in temperature and pressure (isochoric process), followed by the expansion of the gases.

As the piston moves downward during expansion, the volume of the cylinder increases and the pressure tends to remain constant (isobaric process) in the final phase of expansion.

4. Escape (isobaric process)

In the exhaust stage, the exhaust valve opens and the piston moves up again, pushing the burned gases out of the cylinder.

As in the intake stage, the pressure in the cylinder remains relatively constant (at atmospheric pressure) while the volume decreases. This is another example of an isobaric process.

Diesel cycle stages

In the Diesel cycle, efficiency and performance depend on how pressure, volume and temperature are managed within the engine.

In the Diesel cycle, efficiency and performance depend on how pressure, volume and temperature are managed within the engine.

1. Admission (isobaric process)

During the intake phase, the intake valve opens and the piston moves down the cylinder. This allows air to enter the cylinder.

At this stage, the process is isobaric, since the pressure inside the cylinder remains constant at atmospheric pressure while the volume increases due to the downward movement of the piston. Unlike gasoline engines, only air enters this phase in diesel engines, not a mixture of air and fuel.

2. Compression (adiabatic process)

In the compression phase, the intake valve closes and the piston moves upward, compressing the air inside the cylinder.

This process significantly increases the temperature and pressure of the air due to the high compression ratio of the diesel engine, which is not an isobaric process but an adiabatic one, since the pressure changes considerably.

3. Combustion (isobaric and isochoric process)

The combustion phase in a diesel engine begins when the piston is near its highest point (top dead center). At this point, finely atomized diesel fuel is injected into the compressed air.

Due to the high temperature of the compressed air, the fuel ignites spontaneously (self-ignition). Here, combustion is divided into two parts:

- Initial combustion (isochoric process): Initially, the injected fuel burns rapidly, increasing temperature and pressure without a significant change in volume.

- Expansion combustion (isobaric process): More fuel is then injected in a controlled manner, keeping the pressure constant while the volume increases due to the downward movement of the piston. This is an isobaric process and is crucial to diesel engine efficiency as it allows for controlled gas expansion and smoother power delivery.

Escape (isobaric process)

In the exhaust phase, the exhaust valve opens and the piston moves up again, expelling the burned gases out of the cylinder.

Similar to the intake phase, the pressure in the cylinder remains relatively constant (at atmospheric pressure) while the volume decreases. This is another isobaric process.

Differences between Diesel and Otto cycles

In the Otto cycle, isobaric processes occur during intake and exhaust. During intake, the air-fuel mixture enters the cylinder at constant pressure, and during exhaust, the burned gases are expelled at constant pressure. There is no isobaric process during combustion and expansion.

On the other hand, in the diesel cycle, there are also isobaric processes during intake and exhaust, but air is only admitted in the intake. In this case, the Diesel cycle includes an isobaric process during combustion.

After autoignition of the fuel, combustion takes place at constant pressure while the piston descends, allowing controlled burning and efficient expansion of the gases. This difference in the combustion phase contributes to the greater efficiency of the diesel engine compared to the Otto cycle gasoline engine.