The Francis turbine is a hydraulic turbine used in hydraulic power installations operating with a considerable head height.

This turbine was developed by James Bicheno Francis. The function of the Francis turbine is primarily to generate electricity with the help of a generator.

The Francis turbine is the most common type of turbine installed in power generation plants that operate on the basis of mass flow of water through a production facility.

In contrast to the Pelton turbine, the Francis turbine operates at its best completely filled with water at all times.

Performance of a Francis turbine

The performance of a Francis turbine is commonly measured by its hydraulic efficiency, which depends on how well it converts water energy into mechanical energy.

A study of various hydroelectric plants has shown that under ideal conditions, Francis turbines can achieve efficiencies of up to 93% to 95% . This occurs when the water flow and head are within an optimized range, where the turbine operates close to its design point. Under these conditions, the conversion of hydraulic energy into mechanical energy is extremely efficient, and energy losses due to friction and turbulence are minimal.

However, when the turbine is operated outside its design range, for example in cases of fluctuating flow rates or changes in head height, the efficiency can decrease considerably.

En condiciones de carga parcial, la eficiencia puede caer a valores del 85% al 90%. En algunos casos extremos, cuando la turbina opera a caudales muy bajos o a caídas muy altas (fuera de los parámetros óptimos de diseño), la eficiencia puede disminuir incluso por debajo del 80%.

El estudio de una planta hidroeléctrica en los Alpes suizos mostró que, con caudales muy variables, el rendimiento de una turbina Francis puede verse afectado, pero aún se mantiene dentro de un rango de eficiencia de entre el 85% y el 90%, lo que resalta su capacidad de adaptación.

En comparación, otras turbinas, como las Kaplan, pueden tener un rendimiento ligeramente mejor en situaciones de caudal variable, pero con limitaciones en cuanto a la altura de la caída.

Tipo de turbina

La turbina Francis es clasificada como una turbina de reacción. Esto significa que la energía hidráulica que se convierte en energía mecánica no solo proviene de la velocidad del agua, sino también de la diferencia de presión.

A diferencia de las turbinas de impulso, en las que el agua golpea las palas a alta velocidad, las turbinas de reacción como la Francis aprovechan tanto el cambio de presión como el flujo del agua para generar trabajo. En una turbina de reacción, el fluido sigue un camino dentro de la máquina y, a medida que pasa por las palas, su presión disminuye y su velocidad aumenta, lo que resulta en la conversión de la energía del agua en energía rotacional.

Este tipo de turbina es muy eficiente en caídas medias a altas, que suelen ser características de muchas plantas hidroeléctricas, y puede operar en una variedad de condiciones hidráulicas, adaptándose a diferentes caudales y alturas de caída.

Diseño de una turbina Francis

El diseño de esta turbina es altamente especializado para maximizar su eficiencia en una amplia gama de condiciones operativas.

El diseño de esta turbina es altamente especializado para maximizar su eficiencia en una amplia gama de condiciones operativas.

La turbina cuenta con un rotor, que es un conjunto de palas curvadas y dispuestas de forma tal que el agua fluye a través de ellas en un ángulo que optimiza la conversión de energía. El agua entra de manera radial (perpendicular al eje de la turbina) y luego se convierte en un flujo axial (a lo largo del eje). Este diseño es ideal para situaciones de caída media a alta, donde el agua entra con presión y se convierte en energía mecánica de forma eficiente.

Además, la turbina Francis tiene una carcasa espiral que guía el flujo de agua de manera uniforme hacia el rotor, lo que ayuda a reducir las pérdidas de energía por turbulencias y mejora la eficiencia general del sistema. Esta carcasa y el diseño de las palas permiten que la turbina funcione de manera estable incluso cuando las condiciones del caudal y la altura de caída varían.

Aplicaciones de la turbina Francis

Las turbinas Francis de gran tamaño son diseñadas de manera personalizada para maximizar la eficiencia en función de las características específicas de cada sitio, como el suministro de agua y la altura de caída disponible. Su capacidad para adaptarse a diferentes condiciones de caudal y altura de caída las convierte en una opción ideal para plantas hidroeléctricas de gran escala.

Además de su uso principal en la generación de energía eléctrica, las turbinas Francis son ampliamente utilizadas en centrales hidroeléctricas de almacenamiento por bombeo.

En este tipo de instalaciones, se emplean dos embalses situados a diferentes alturas. Durante períodos de baja demanda energética, el exceso de energía disponible es utilizado para bombear agua desde el embalse inferior al superior. En este proceso, la turbina Francis actúa como una bomba, utilizando un generador eléctrico que funciona como un motor para realizar el bombeo de agua.

Cuando la demanda de electricidad aumenta, el generador eléctrico se invierte y comienza a generar electricidad utilizando el agua almacenada en el embalse superior. Este sistema de almacenamiento permite equilibrar las fluctuaciones de la demanda energética, haciendo de las turbinas Francis una opción eficiente y flexible para plantas hidroeléctricas que necesitan operar bajo diferentes condiciones de carga.

Ventajas y desventajas de la turbina Francis

Ventajas principales

- Facilidad de control en condiciones variables: La turbina Francis es muy fácil de controlar, incluso cuando la altura de caída y el caudal del agua fluctúan, lo que permite su funcionamiento eficiente en diversas condiciones operativas.

- Alta estabilidad en eficiencia: La variación de su eficiencia con el paso del tiempo es mínima, lo que garantiza un rendimiento confiable y duradero a lo largo de su vida útil.

- Tamaño compacto: El tamaño del corredor de la turbina Francis es relativamente pequeño en comparación con otros tipos de turbinas, lo que permite una instalación más compacta y menos costosa.

- Bajo costo de mantenimiento: En comparación con otras turbinas hidráulicas, las turbinas Francis requieren un mantenimiento relativamente bajo, lo que contribuye a una mayor rentabilidad y reducción de costes operativos.

Desventajas principales

- Diseño específico para caudal determinado: Las turbinas Francis están diseñadas para operar de manera óptima con un caudal específico. No son la mejor opción para instalaciones que experimentan grandes variaciones de caudal, ya que el rendimiento puede disminuir considerablemente en tales condiciones.

- Limitaciones con alturas de caída mayores a 800 m: Aunque es eficiente en caídas medias a altas, la turbina Francis presenta problemas de rendimiento cuando se utiliza en alturas superiores a los 800 metros, debido a las altas presiones que pueden generar.

- Risk of cavitation : Like other reaction turbines, Francis turbines can suffer from cavitation, a phenomenon that occurs when the water pressure at the turbine inlet drops too low, causing the formation of steam bubbles that damage the blades and reduce efficiency.

- Sensitivity to dirty water : The entry of water with particles or impurities can cause significant problems for the turbine, since these particles can damage internal components, such as the blades and the impeller, reducing the life of the turbine and affecting its performance.

Parts of a Francis turbine

The Francis turbine, designed by James B. Francis, consists of several key components that work together to optimize its efficiency and energy conversion. Its main parts are described below:

- Spiral chamber : This part has the function of distributing the fluid along the impeller inlet. Its spiral or snail shape ensures that the average speed of the fluid remains constant as it heads towards the rotor. This allows the water to flow evenly, reducing losses and ensuring efficient performance at the system inlet.

- Predistributor : Made up of fixed vanes, the predistributor has a key structural function, as it prepares the water flow before it enters the distributor. Its hydrodynamic design is optimized to minimize hydraulic losses and ensure that the fluid efficiently reaches the next component, with a laminar flow that reduces turbulence.

- Distributor : The distributor consists of movable blades that direct water towards the fixed blades of the runner and regulate the admitted flow. It also adjusts the direction of the flow to improve overall performance and allow the turbine to respond to load variations in the electrical grid. This component, known as the Fink distributor , is crucial for regulating the turbine's power based on operating conditions.

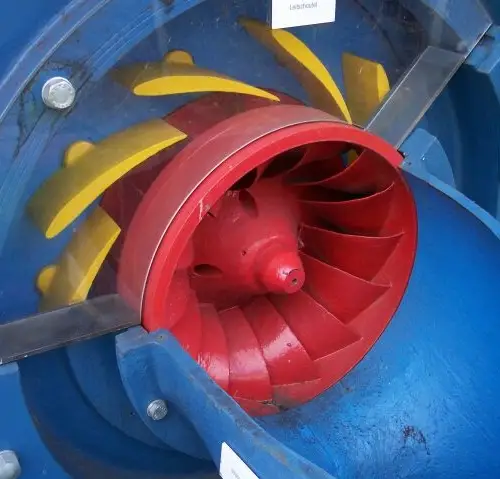

- Rotor or impeller : This is the fundamental component in which energy exchange takes place. The rotor converts hydraulic energy, which includes the pressure and kinetic energy of the water, into mechanical rotational energy. This rotational energy is transferred to an electric generator, converting it into electrical energy. The design of the impeller blades allows for efficient and stable conversion of fluid energy.

- Suction tube : This is the outlet of the turbine, through which the water, once used to generate energy, is evacuated from the system. The design of the suction tube is optimized to reduce energy losses at the flow outlet, ensuring that the turbine operates efficiently throughout the process.