Solar thermal collectors (also known as solar collectors) are devices designed to capture and convert the sun's energy into useful heat. This technology is essential for applications requiring water heating, space heating or industrial processes.

Compared to photovoltaic panels, which convert sunlight directly into electricity, solar thermal collectors are specialized in heat production. Their efficiency and diverse applications have made them a popular choice for improving energy efficiency and reducing dependence on fossil fuels.

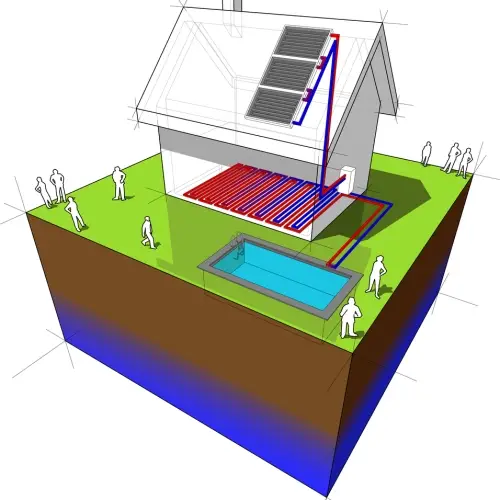

There are many types of solar thermal energy installations depending on the purpose for which they are designed. Some common uses of solar collectors are:

- Heating systems.

- Heating pool water.

- Domestic hot water (DHW)

- Electricity production in large solar thermal power plants.

Operating principle

Solar thermal collectors work based on the principle of absorbing solar energy. Although there are different types of solar collectors, as we will see later, the operating principle is similar in all of them.

Solar thermal collectors work based on the principle of absorbing solar energy. Although there are different types of solar collectors, as we will see later, the operating principle is similar in all of them.

First, solar radiation strikes an absorbing surface which converts radiant energy into thermal energy. This thermal energy is transferred to a transfer fluid (usually water or a mixture of water and antifreeze) which circulates through the collector.

Finally, the hot fluid is then used differently depending on the application in which it is used or stored for later use.

Types of solar thermal collectors

There are many types of solar collectors. The solar collector used will depend on the use that will be given to it. Currently, in the solar energy market we can differentiate the following types of solar collectors:

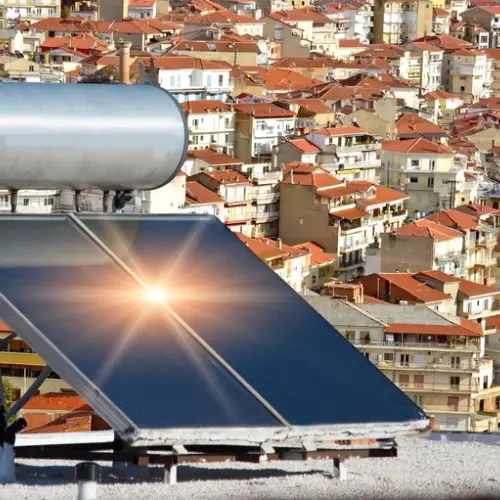

Flat (or flat plate) solar collectors

Flat panel solar collectors are the most common type and are primarily used to heat water for domestic use, swimming pools and industrial applications.

This type of collector captures solar radiation received on a surface to heat a fluid. The greenhouse effect is often used to reduce heat loss.

The core of this type of flat plate solar collector is a set of vertically oriented metal tubes that conduct cold water in parallel. These tubes are connected from below by a horizontal tube to the cold water inlet and another similar tube to the outlet at the top.

The set of tubes is enclosed by a cover at the top, which is normally made of double glass, and by an insulating material at the bottom.

Main Features

- Simple design: The construction of flat solar collectors is relatively simple, which contributes to their low cost compared to other types of collectors.

- Efficiency in moderate climates: They are most efficient in warm and moderate climates where heat losses are lower. In cold climates, they may lose more heat, which can reduce their efficiency.

- Common Applications: They are commonly used in residential and swimming pool water heating systems, as well as in commercial and industrial applications.

How a flat plate collector works

In a flat solar collector, the absorber plate is exposed to the sun and is heated by absorbing solar radiation. The heat transfer fluid, which circulates through tubes on the back of the plate, absorbs the heat from the plate.

The hot fluid is transported to the storage system so that it can be used when required to heat water or air.

Vacuum tube collectors

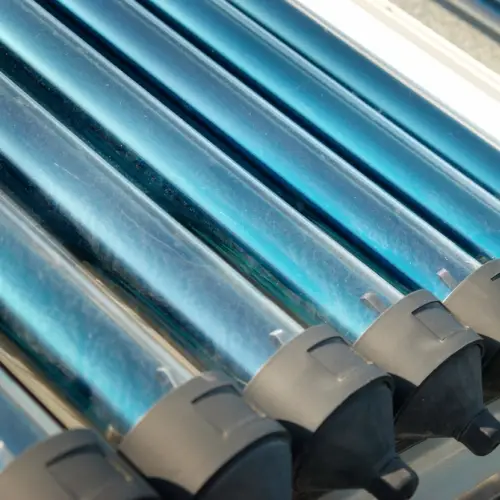

A vacuum tube solar collector is similar to a flat plate solar collector but the metal tubes are replaced by glass tubes. These glass tubes are encapsulated, one by one, in another glass tube between which a vacuum is created for insulation. Each tube contains an inner absorber tube which is in contact with the heat transfer fluid.

A vacuum tube solar collector is similar to a flat plate solar collector but the metal tubes are replaced by glass tubes. These glass tubes are encapsulated, one by one, in another glass tube between which a vacuum is created for insulation. Each tube contains an inner absorber tube which is in contact with the heat transfer fluid.

This type of solar thermal panels have a higher performance but their cost is higher.

Main Features

- High efficiency: Vacuum tube collectors are more efficient than flat plate collectors, especially in cold and cloudy climates. The vacuum between the glass tubes provides excellent thermal insulation, reducing heat losses.

- Greater performance in adverse weather conditions: Its design allows for high efficiency even on cold and cloudy days, as the vacuum between the tubes acts as a barrier against heat loss.

- Special applications: They are used in applications that require high performance in adverse weather conditions, such as water heating in cold regions or for industrial processes that require high temperatures.

How a vacuum tube pickup works

In evacuated tube collectors, solar radiation strikes glass tubes, heating the inner absorber tube. The heat transfer fluid circulates inside the absorber tube, where it collects the heat and transports it to the storage system.

The feature that makes them special is that the vacuum between the glass tubes minimizes heat loss to the environment and therefore they are more efficient.

Air collectors

Air collectors are a less common type of solar thermal collector that heats air instead of water. These collectors are designed for space heating and agricultural product drying applications.

Main Features

- Simple design: Air collectors are typically simpler in construction than the water collectors mentioned above, as they do not require a heat transfer tube system.

- Use in space heating: They are suitable for space heating, such as greenhouses or buildings, and also for drying processes where hot air is needed.

- Lower cost: They are generally lower in cost than traditional water collectors due to their simpler design and lower complexity.

Functioning

In an air collector, solar radiation heats the air circulating through the collector. The warm air is collected and used for space heating or industrial applications. These collectors are usually of the flat or evacuated tube type, but with specific adaptations for air flow rather than liquid fluid.

Hybrid collectors (photovoltaic-thermal or PVT)

Hybrid collectors combine solar photovoltaic and thermal technologies, allowing for the simultaneous generation of electricity and heat. These systems are designed to improve the overall efficiency of solar energy collection by harnessing both types of energy.

General characteristics

- Dual power generation: PVT collectors produce both electricity and heat, which can be more efficient in terms of space and resource use.

- Diversity of applications: They are suitable for residential and commercial uses where both heating and electricity generation are required, such as in water heating systems and home power generation.

- Cost and complexity: They have a higher initial cost and greater complexity compared to individual solar thermal or photovoltaic collectors.

Functioning

Hybrid collectors combine photovoltaic panels with an absorber plate to generate heat. Solar radiation is converted into electricity by photovoltaic cells and into heat by the absorber plate.

On the one hand, the heat produced is transferred to a storage system, while the electricity can be used directly or stored in batteries.

Concentrating solar collectors

This type of collector captures the radiation received on a relatively large surface and concentrates it using flat mirrors on a smaller surface.

Although concentrating collectors have different characteristics and applications compared to flat plate and evacuated tube collectors, they are still a form of solar thermal collectors as they all have the common objective of converting solar energy into heat.

The function of a concentrating solar collector is to focus all the solar energy received on a surface at one point to obtain high temperatures. This technique is used in high and very high temperature solar installations.

Typically, this type of solar collector is used to generate very high pressure steam and generate electricity as in a conventional thermal power plant .

There are several types of solar concentrators, which we describe below:

Parabolic cylindrical collectors

Parabolic trough collectors use mirrors shaped like a cylindrical paraboloid to concentrate sunlight onto a receiver tube located along the axis of the mirror. The reflected sunlight heats a thermal fluid inside the tube, which is then used to generate steam and produce electricity in a solar power plant.

Parabolic trough collectors use mirrors shaped like a cylindrical paraboloid to concentrate sunlight onto a receiver tube located along the axis of the mirror. The reflected sunlight heats a thermal fluid inside the tube, which is then used to generate steam and produce electricity in a solar power plant.

This type of collector is highly efficient in converting solar energy into heat and is used in industrial applications and large-scale electricity generation facilities.

Central tower collectors

Central tower collectors consist of a tower surrounded by a field of mirrors (heliostats) that follow the movement of the sun to reflect sunlight onto a receiver at the top of the tower. The receiver captures the concentrated light and converts it into heat, which can be used to generate steam and produce electricity.

Central tower collectors consist of a tower surrounded by a field of mirrors (heliostats) that follow the movement of the sun to reflect sunlight onto a receiver at the top of the tower. The receiver captures the concentrated light and converts it into heat, which can be used to generate steam and produce electricity.

This type of collector is ideal for large solar power plants as it can reach extremely high temperatures and offers high efficiency in power generation.

Linear Fresnel Concentrators

Linear Fresnel concentrators use a series of flat or slightly curved mirrors to concentrate sunlight onto a fixed linear receiver. The light concentration heats a thermal fluid that flows through the receiver, and this heat is used to generate steam or electricity.

Linear Fresnel concentrators use a series of flat or slightly curved mirrors to concentrate sunlight onto a fixed linear receiver. The light concentration heats a thermal fluid that flows through the receiver, and this heat is used to generate steam or electricity.

These collectors are cheaper than parabolic troughs and are suitable for medium-scale applications, offering a good balance between cost and efficiency in areas with high solar irradiation.

Advantages and disadvantages of solar thermal collectors

Advantages

- Reduced energy costs: Solar thermal collectors can significantly reduce energy costs by harnessing free solar energy.

- Environmental sustainability: They contribute to the reduction of greenhouse gas emissions and the use of renewable energy sources.

- Diversity of applications: They are versatile and can be used in a wide range of applications, from domestic heating to industrial processes.

- Low maintenance: They generally require little maintenance and have a long lifespan.

Disadvantages

- Initial cost: The initial cost of installing solar thermal collectors can be high, although it is often recovered over time through savings in energy costs.

- Climate dependence: The efficiency of solar thermal collectors depends on the availability of sunlight, which can limit their effectiveness in cloudy regions or during winter.

- Space Required: Solar thermal collector systems require adequate surface area for installation, which can be a limitation in areas with limited space.

- Heat storage: A storage system is needed to utilize the heat when the sun is not present, which can increase the cost and complexity of the system.

Energy saving

Using solar thermal collectors in a normal home can generate significant energy savings compared to a home that does not use them. By harnessing the sun's energy to heat water, solar thermal collectors would significantly reduce the need for traditional water heating systems, which typically rely on electricity or fossil fuels.

Using solar thermal collectors in a normal home can generate significant energy savings compared to a home that does not use them. By harnessing the sun's energy to heat water, solar thermal collectors would significantly reduce the need for traditional water heating systems, which typically rely on electricity or fossil fuels.

A study by the International Renewable Energy Agency (IRENA) indicates that solar thermal collector systems can cover between 50% and 80% of the hot water needs in a typical home depending on the geographic location and the efficiency of the system.

On the other hand, according to the United States Environmental Protection Agency (EPA) , solar thermal systems can reduce water heating costs by 50% to 70%. In Europe, a typical household could save approximately €200 to €280 annually on an average €400 per year water heating bill.

For all these reasons, it is estimated that the initial investment in solar thermal collector systems can be recovered in a period of 5 to 10 years thanks to the accumulated energy savings, depending on local incentives and the cost of traditional fuels.

Future and development

Solar thermal collector technology continues to evolve, with advances in materials, design and efficiency.

Solar thermal collector technology continues to evolve, with advances in materials, design and efficiency.

Currently, research is focused on improving the efficiency of solar thermal collectors through new absorbent materials and insulation techniques.

On the other hand, hybrid systems that combine photovoltaic and thermal technologies are gaining popularity, offering greater efficiency and versatility.

On the cost side, reduced manufacturing costs and the adoption of new technologies may make solar thermal collectors more accessible for a wider range of applications.